‘Fan of Innovation’ Puts Tech Expertise to Work in Agriculture

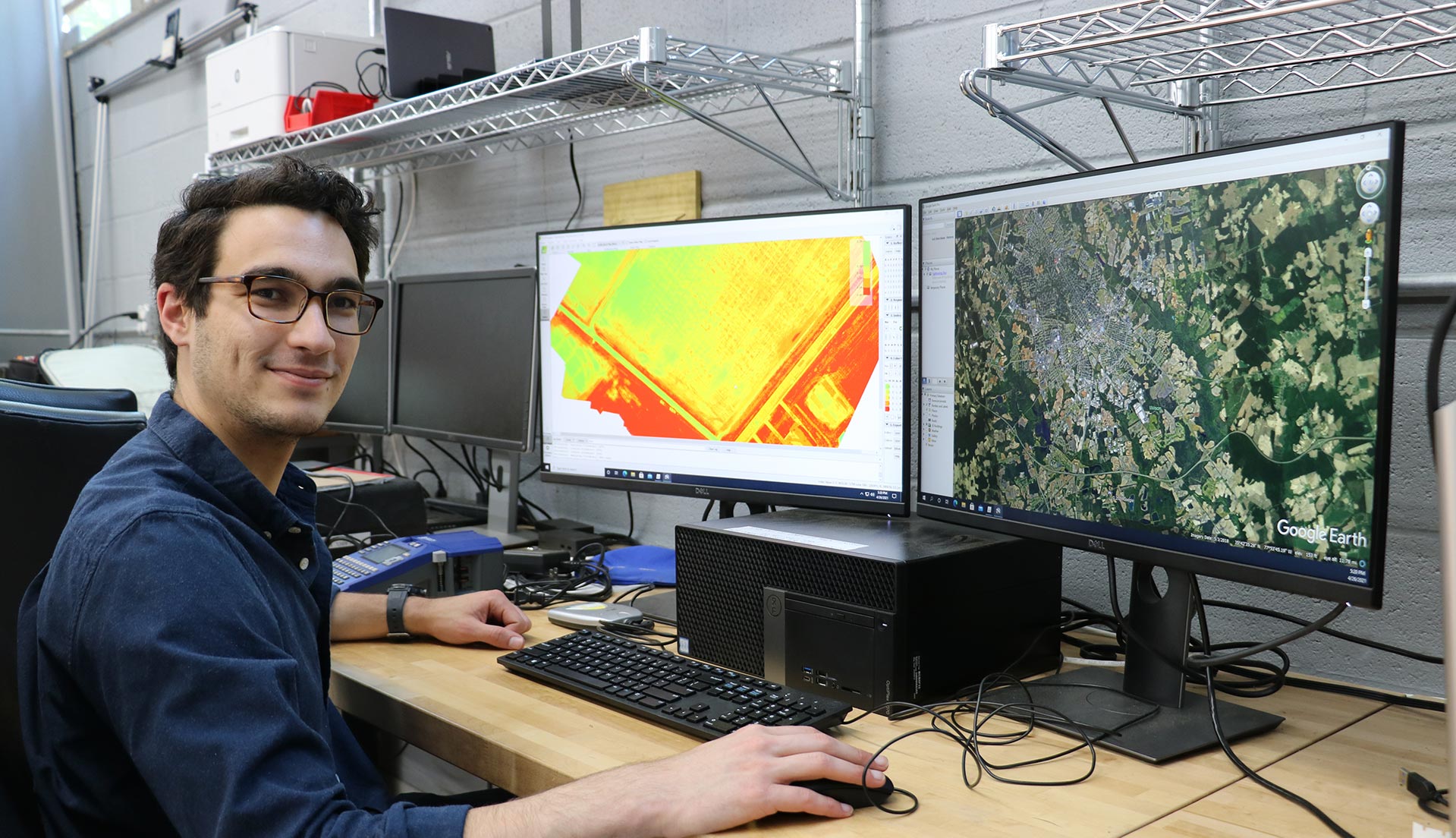

Drawing on expertise gained as an NC State doctoral student in electrical engineering, Enrique Peña Martinez launches a career in agricultural technology. His goal: to help reduce the challenges that come with farming and increase its rewards.

July 14, 2025 ![]() Colleen Brown

Colleen Brown

While recent North Carolina State University graduate Enrique Peña Martinez didn’t grow up on a farm, he realizes there’s nothing else like agriculture.

“I like touching the soil and talking to farmers,” he says. “It’s helped me appreciate how fragile life is and how farming, while it’s so stressful, can also be so rewarding.”

Peña Martinez has made it his mission to develop technology that increases farming’s rewards while reducing the stress.

“I’ve always been a fan of innovation, looking at what are the best ways to improve working conditions and the value of crops through technology,” Peña Martinez explains. “What drives me is understanding how we can create new technologies that farmers will adopt — how we close the gap that exists between technology development and its application in the field.”

In May, he hit a major milestone in his journey as an agricultural innovator, earning his doctorate from NC State’s Department of Electrical and Computer Engineering. He’ll take another step forward in September, when he joins AMADAS Industries, a Virginia-based company that manufactures advanced systems for harvesting peanuts.

At NC State, Peña Martinez gained experience working across disciplines and directly with sweetpotato packers and peanut breeders to develop problem-solving technology.

With Mike Kudenov, a College of Engineering professor affiliated with the N.C. Plant Sciences Initiative, he focused on ways to make sorting and grading harvested crops more efficient and affordable.

To come up with solutions, Peña Martinez drew on the fields of agricultural engineering, optical sensing and machine learning, a branch of artificial intelligence that focuses on using data and algorithms to teach computers to perform specific tasks.

Building an Affordable, Yet High-Tech, System for Sweetpotatoes

For sweetpotato packers, Peña Martinez helped build a high-speed system that could be a game-changer. It uses low-cost cameras at strategic points in the postharvest process to accurately scan and grade their produce.

As he, Kudenov and their N.C. PSI collaborators note in a paper published in Smart Agricultural Technology last summer, such tools can help packers better understand their inventories, fulfill orders more efficiently and cut down on waste.

“We very actively collaborated with packers. … We had our ideas, but ultimately what we really cared about is what they cared about.”

The system has important implications in North Carolina, where sweetpotatoes bring in $255 million annually. That makes North Carolina the nation’s leading sweetpotato producing state.

While some of North Carolina’s largest sweetpotato packers already use AI-based scanning-and-sorting systems, the systems’ price tags put them out of reach for typical operations.

While Peña Martinez refers to the solutions as “disruptive,” he means that in the best possible way. Throughout his research, he took pains to ensure they would be as easy as possible for packers to adopt.

“We very actively collaborated with packers — and by this, I mean meeting with them almost at a weekly basis, talking with them, prototyping a lot with them so that they drove the conversation on what they wanted,” he says. “We had our ideas, but ultimately what we really cared about is what they cared about.”

Adapting Scanning Tech for Peanut Breeders and Buying Stations

Peña Martinez also worked to adapt similar technology for peanut sizing and grading. Jeffrey Dunne, an associate professor and peanut breeder with NC State’s Department of Crop and Soil Sciences, collaborated on the project.

“We’ve been able to incorporate a low-cost scanner, similar to the one for sweetpotatoes, into a conventional peanut pre-sizer and a sheller to enable digital phenotyping at a breeding facility,” he says. Phenotyping involves determining, analyzing and predicting observable traits, such as size, shape and color.

“We’re not really getting rid of any conventional system. We are trying to compare what would happen if we incorporated these scanners: Can we get the same data essentially and make it digital?”

Such tools, Peña Martinez says, could be used not only by scientists who rely on data on peanut size and other factors to produce superior varieties, but also in peanut buying stations, where peanuts are graded and inspected before they’re marketed.

The Roots of Peña Martinez’s Passion

Through his Ph.D. research, Peña Martinez pursued a passion for improving agricultural technologies that took root in his childhood. His grandfather kept a vegetable garden on his rooftop in the Dominican Republic, and Peña Martinez worked by his side to construct hydroponic systems and raised beds for the garden.

His grandmother, a university professor, was also an influence. Noticing Peña Martinez had a knack for investigation, she suggested he consider agricultural engineering.

After high school, he entered the Santo Domingo Institute of Technology, or INTEC, then completed a bachelor’s degree in biological engineering at Penn State University.

A grueling college internship on a Dominican citrus farm that lacked modern equipment reinforced Peña Martinez’s decision to be an agricultural innovator. He wanted to find ways to make farming easier and more sustainable.

Gaining a Broad Understanding of Advanced Technologies

For his graduate studies, he came to NC State in 2019 to work with Jason Ward, an associate professor, Extension specialist and precision farming expert in the Department of Biological and Agricultural Engineering.

As a master’s student, Peña Martinez studied ways to use drones and remote sensing and optical sensing tools to help cotton farmers make complicated decisions about replanting so-called “skips” — places in a field where plants are missing from rows because the planter didn’t properly place the seeds or the seeds didn’t germinate.

As he conducted that research, Peña Martinez found himself wanting to know more about the artificial intelligence, data analysis and electrical and computer engineering that went into the technology he was using.

“In the Plant Sciences Building, everyone works so collaboratively. There are many different engineers, plant scientists and data scientists, all working together.”

That curiosity led Peña Martinez to Kudenov’s lab and a place on NC State’s Sweet-APPS team.

With the goal of developing new technologies to minimize waste and maximize value for sweetpotato producers and packers, Sweet-APPS kicked off in 2020 as one of the N.C. Plant Science Initiative’s inaugural research projects.

Peña Martinez says that being part of the N.C. PSI helped him make the not-so-easy leap from a master’s in biological and agricultural engineering to a Ph.D. in electrical engineering.

“It was a big challenge, but in the Plant Sciences Building, everyone works so collaboratively. There are many different engineers, plant scientists and data scientists, all working together,” he says. “That made it easier.”

Looking Ahead

Peña Martinez is proud to see the high-throughput system he helped develop being used at an industrial scale, and he’s eager for the next challenge.

This summer, he’s collaborating with Rijk Zwaan, an international vegetable seed breeding company that has operations in the United States.

“Here in North Carolina, Rijk Zwaan is big on cucumber trials, so I am helping the company start their digital phenotyping efforts to speed up and improve cucumber grading,” he says. “I am also helping their crop specialists with manual labor and spending a lot of time in the field.”

Meanwhile, Peña Martinez is looking forward to starting work with AMADAS as an advanced technologies engineer. In that role, he’ll be developing optical sensing systems for next-generation peanut combines.

When it comes to helping farmers increase profits and reduce waste, he says, “there is still so much room for growth. I am excited for this opportunity to continue being a part of this movement.”